扫一扫 联系我们

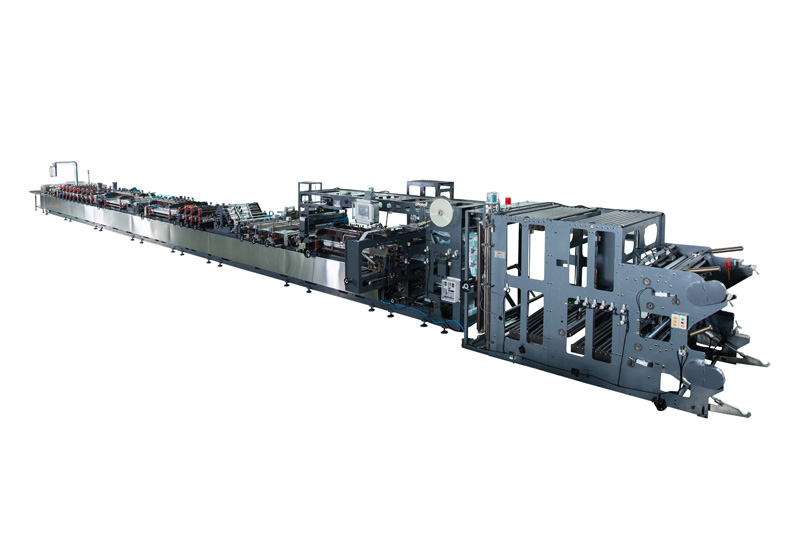

| Model | SKB700-BPZDN-MTF Four Lanes Box Pouch Bag Making Machine | ||||

| Optional Model | 700 | 800 | Customization | ||

| Film Material | CPP,PET,OPP,PAPER and all kinds of laminating films | ||||

| Film Size | Main film Max. Width:1200mm、Max. Diameter:φ800mm Gusset film Max. Width: 410mm,Max. Diameter:φ600mm Bottom film Max. Width:170mm,Max. Diameter:φ600mm The film size is the same for standard three side seal bags. |

||||

| Rewinding Form of Main Film | Horizontal Film Axis Type • M-Plate Mode • Tension Control Magnetic Brake, Non-stop unwinding matching Automatic Joint Detection Function AC Motor Driving System with inverter Detection of printing color label by color label sensor |

||||

| Rewinding Form of Gusset Film | Horizontal Film Axis Type, Center Seal Forming mode,Tension Control Magnetic Brake,Non-stop unwinding matching Automatic Joint Detection Function AC Motor Driving System with inverter Detection of printing color label by color label sensor |

||||

| Rewinding Form of Bottom Film | Vertical Film Axis Type,Center Seal Forming mode,Tension Control Magnetic Brake, Non-stop unwinding matching Automatic Joint Detection Function AC Motor Driving System with inverter Detection of printing color label by color label sensor |

||||

| Bag-making Function | 3 lanes three side seal with zipper, four lanes box pouch | ||||

| Bag-making speed | 110shots/min | Unwind line Speed | 30m/min | ||

| Bag-making Size | Single: Bag length:200-640mm,Bag width:100-380mm,Gusset depth:35-100mm,Bottom depth:35-70mm Four: Bag length:90-150mm,Bag width:60-150mm,Gusset depth:20-50mm,Bottom depth:25-50mm |

||||

| Bad exclusion function | At the beginning of operation, in order to prevent the incorporation of bad heat sealing bags, a film with arbitrary distance is set from the cutting knife to remove double feeding. | ||||

| Electrical Matching | Main servo motor:1set,5KW. Traction servo motor:5sets,1.5KW—3set,2KW—2set. Gusset unwinding servo motor:2KW—1set,Gusset location:1.0KW—1set Gusset cutter servo:0.75KW—1set, Gusset hotpress:1.5KW—1set Bottom location servo:0.75KW—1set Double cutter:1.0KW,0.75KW—each 1set Feeding AC motor:6set,0.4KW—2set,0.2KW—4set. Feeding inverter:6ser,0.75KW—2set,0.4KW—4set. |

||||

| Electrical Matching | Total Power 70KW,380V,50HZ |

Cooling Water 10L/min |

Air Pressure 0.6MPa(6Kgf/)cm² |

||

| Machine Dimensions | L*W*H:20000*3000*2300mm (By the selected function to determine the final size) | ||||

| Option function | 2lanes zipper function | Main web with registration control function | |||

| Fully automatic coffee valve | Fully automatic on-line die cutting | ||||

| Fully automatic slider zipper | Fully automatic pocket zipper | ||||

| Fly-cutter | carry handle on side gusset | ||||

| New Model | Automatic Detection Bag Strapping Machine | ||||